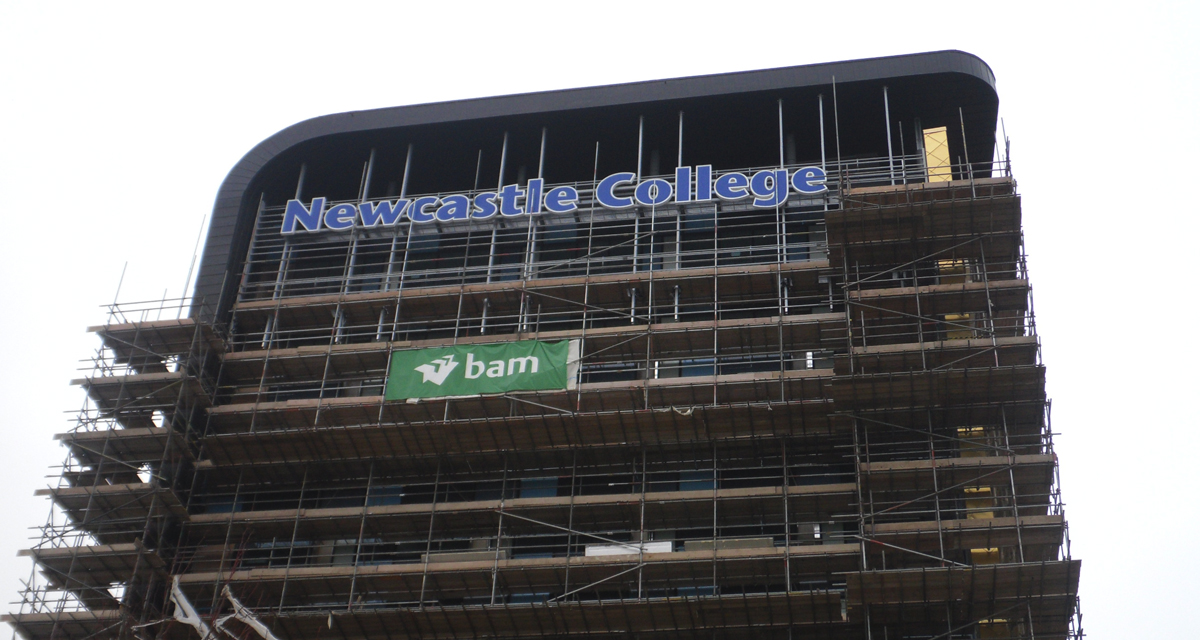

Parsons Tower Newcastle

Architect

Red Box Architecture

Value

£865,000

Contractor

BAM Construction Ltd

This £18 million facility wrapped in Copper and Zinc Roofing and Cladding has undergone an amazing redevelopment and is home to business, uniformed public services, healthcare and childcare courses.

Zinc Roofing and Cladding in the North East!

BAM Construction was the main contractor tasked with renovating the existing building, and chose Longworth to partner them on the scheme due to our wealth of experience with zinc roofing and cladding, composite panels and flat roofing.

The new facilities include student-run shops, learner zones, social spaces, hospital training wards, childcare training rooms and science laboratories. There is also a five-bed ward complete with nurse’s station, a six-bed ward with accessible bathroom and electric hoist, a two-bed paediatric ward and a two-bed intensive care ward.

The biggest challenge faced on this project was working on an existing building. The existing columns and floor slabs had moved over time, creating lining and leveling issues for the composite wall panels. This was overcome by introducing a secondary steel framing system between the composite panels and existing structure to bring a degree of flexibility to the walls.

The composite wall panels were specified as the Rainspan panel from Eurobond. Due to the height of the building and fire regulations, the core of the panel was a structural stone wool, which made the panels twice the normal weight. This presented issues with manual handling and loading out of the floors using the hoist.

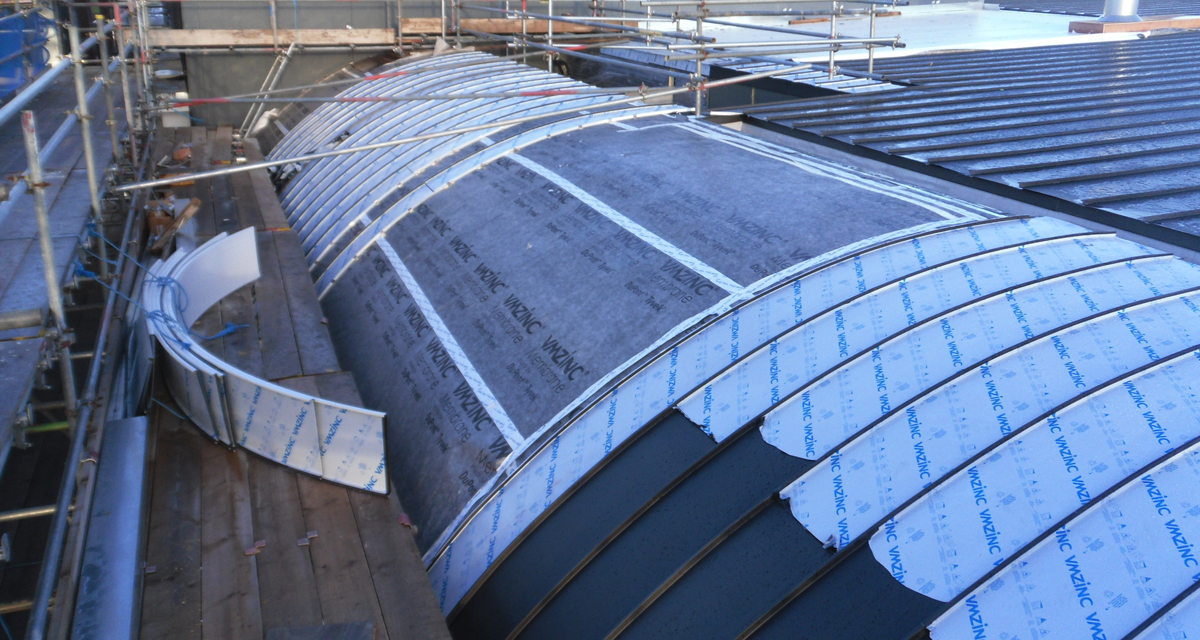

There were both convex and concave curved panels on the project which required pre-curved panels. The convex panels were curved off site using an arch bending machine, and the concave panels were formed on site using a purpose made attachment to the panel profiling machine.

Copper Shingles and Zinc Standing Seam

The eastern elevation is adorned with TECU Gold copper, diamond shingles facade. It provides a stark contrast to the Anthra and Quartz Standing Seam Zinc Roofing and Cladding on the other 3 elevations and is a real statement elevation.

Zinc roofing and cladding challenges

The tight conditions with it being a city centre location meant that there was only space on site for one skip. This resulted in a concerted effort to keep waste to an absolute minimum: the composite panels were scheduled from drawings to ensure that no cutting was required on site; all off-cuts of single ply membrane and zinc were brought back from site for recycling; all packaging was taken to a local recycling facility.

We employed the services of a local fabrication company for the standard galvanised steel profiles and aluminium flashings. This reduced emissions for deliveries from our offices in Haydock.

All labour used on the project was from the local area, from joiners and single ply membrane roofers to the zinc craftsmen.

Looking at the before and after pictures of the project it is hard to believe that it is the same building. We are very pleased with the final finish of the project which is a prominent feature at the entrance to Newcastle from the A1.

Specification

- VM Zinc Anthra & Quartz + full substrate

- TECU Gold copper, diamond shingles

- ACM Cladding

- Aluminium column casings

Team Members involved

Lee Smith

Contracts Director

Robert Hughes

Operations Director

Karl Smith

Commercial Director

Products Used

Fully supported metal roofing & claddingWhat our clients say

"We’re really pleased with the proactive effort put in by Longworth to ensure the desired quality is achieved. The building is well received by everyone and regarded as a success."Husnee Jamalluddin - Associate, Halsall Lloyd Partnership